At Chatsworth Products (CPI), we offer a comprehensive suite of ICT infrastructure solutions designed to meet the evolving needs of the semiconductor industry. From sub-fabrication (sub-fab) areas and central utility buildings (CUBs) to cleanrooms and onsite data centers, our products are engineered to enhance efficiency, ensure reliability, and support rapid production. Whether you're focused on improving yield, reducing downtime, or achieving sustainability, CPI is your partner for success.

Enhance Your Sub-Fab and Cleanroom Operations

In semiconductor manufacturing, precision environmental control and uptime are critical. CPI provides cleanroom-compliant racks, enclosures, intelligent PDUs, and cable management solutions that support your sub-fab's unique requirements.

Explore our Solution

|

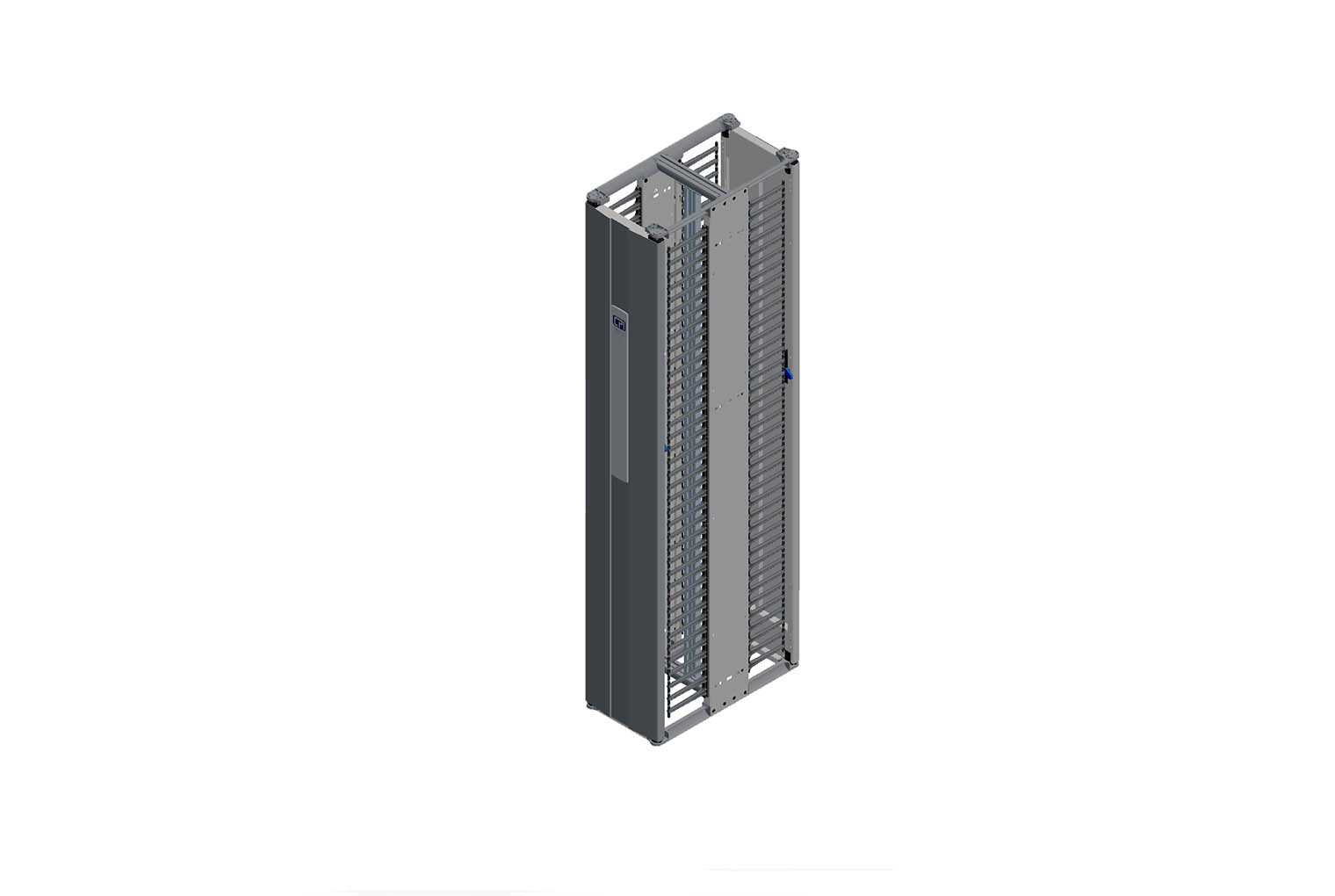

ZetaFrame® Cabinet System

A highly engineered data center cabinet solution that delivers fast built-to-order configurability, industry-leading strength and scalability, regardless of the application.

|

|

Motive® Vertical Cable Manager is a highly configurable and advanced cable management solution that provides unlimited adjustment anywhere within the cable manager, optimizing use of interior space.

|

|

Switched Pro eConnect® PDU

Switched Pro eConnect® PDUs provide remote power monitoring and control for each outlet on the PDU, making it possible to remotely measure and cycle power for each piece of equipment attached to the PDU.

|

|

VL Series — Reliable and economical backup power protection for servers and network applications.

|

|

Creates a flexible point-to-point pathway for network cabling in data centers, entrance rooms, distribution areas (MDA, HDA), telecommunications rooms and other spaces where cabling enters or exits the pathway.

|

|

Economical, locking, suspended ceiling Wi-Tile enclosure mounts and secures Wi-Fi APs flush to the ceiling.

|

Explore how our solutions can enhance your FAB and cleanroom environments by booking a

personalized consultation with one of our experts.

Power Your Semiconductor CUB

Maintaining uptime in your CUB and data centers is essential to the smooth operation of semiconductor manufacturing. CPI offers the

ZetaFrame® Cabinet System, which is designed to provide flexibility, strength, and optimized airflow. Coupled with our

intelligent power distribution units (PDUs) and advanced security features, you can ensure the reliability and scalability your CUB and data centers require.

Ready to optimize your CUB and data center operations?

Discover how our cutting-edge infrastructure solutions can drive efficiency.

Explore our Solution

|

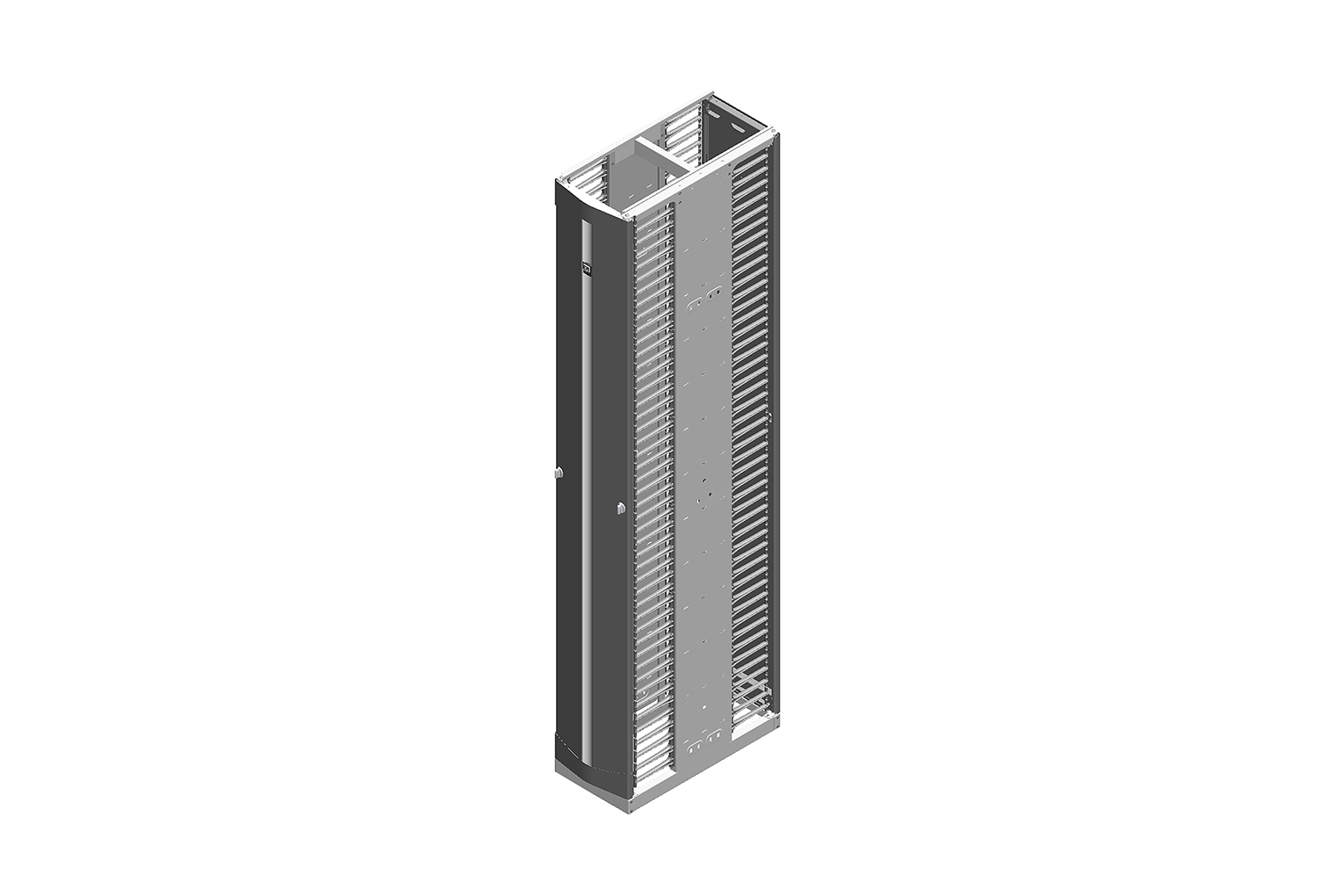

Adjustable Rail ServerRack

The Adjustable Rail ServerRack (ARSR) provides a sturdy, feature-rich solution for supporting rack-mount equipment in data centers, computer equipment rooms and other IT facilities. Rear square-punched mounting rails adjust in depth.

|

|

Evolution® Double-Sided Vertical Cable Manager

Evolution® Cable Management System is a reliable, feature-rich cable management solution with faster deployment times that delivers increased performance to match the demands of today’s high-density data center applications.

|

|

Monitored eConnect® PDU

Monitored eConnect® PDUs provide remote power monitoring to the input and branch circuit level, making it possible to obtain and manage power consumption at the cabinet level.

|

|

VL Series — Reliable and economical backup power protection for servers and network applications.

|

|

Creates a flexible point-to-point pathway for network cabling in data centers, entrance rooms, distribution areas (MDA, HDA), telecommunications rooms and other spaces where cabling enters or exits the pathway.

|

|

Economical, locking, suspended ceiling Wi-Tile enclosure mounts and secures Wi-Fi APs flush to the ceiling.

|

Drive Efficiency with Edge Computing Solutions

As semiconductor manufacturers move toward smart manufacturing, the need for real-time data processing has never been greater. CPI’s edge computing solutions—including industrial enclosures, micro data centers, and intelligent PDUs—are designed to support edge environments that demand rapid production and customization. Our solutions promote sustainability while delivering the performance necessary for advanced manufacturing processes.