Seasoned data center managers and cable installation pros have seen it all. Cables bunched too tight, strained at awkward angles, or dangerously close to their minimum bend radius. Even Cat6A cables stretched so taut they could be plucked like guitar strings.

Now, with the explosive rise of 400G Ethernet and high-density networks, traditional cable management is struggling to keep up. Fixed systems are no longer cutting it, unable to adapt to the constantly shifting layouts and growing demands of today’s high-performance data centers.

The Need for Flexibility

Traditional fixed cable runway systems, while reliable, can cause several problems in modern data centers:

Why Choose Adjustable Cable Runways?

An adjustable cable runway offers flexibility, allowing technicians to reposition features like cross members and accessories to preserve bend radii and align with infrastructure changes. For example, CPI’s Adjustable Cable Runway addresses issues with several key features:

-

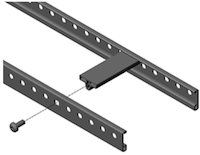

Movable Cross Members: Cross members can be easily relocated by removing two screws, allowing for quick cable drops while maintaining network integrity. They can be adjusted up to 4" (101 mm) from their original position, maintaining load capacity and an appropriate load rating.

-

Standards Compliance: Meets ANSI, TIA, and EIA standards for copper and fiber cabling, ensuring proper bend radii and data transmission integrity.

Unlike traditional welded runway systems, this design allows for ultimate cable pathway customization, providing flexibility as needs change.

Watch this video to see how CPI's Adjustable Cable Runway can save you time and simplify project specifications:

When to Use Adjustable Cable Runway

Adjustable cable runways are perfect for environments where the runway supports cabling above racks, cabinets, and vertical cable managers. Installers can easily reposition cross members along the side stringers to accommodate cable entry and exit points, providing the flexibility to customize pathways without excessive tools or labor.

This adaptability is especially useful in dynamic data centers where frequent changes are common. As Avery Aragaki, Partner at Aspen Technologies, says, "There is no downtime to tear everything down and move everything around."

With quick adjustments that don’t disrupt the entire system, CPI’s solution helps maintain optimal performance while reducing maintenance time and costs.

How to Adjust the Cross Members

To move cross members, installers would use a T40 (TORX) hexalobular driver to loosen and remove the hardware. Once removed, the cross members slide freely along the runway. After positioning, secure the cross members with the same hardware.

What about grounding and bonding?

Like any metal pathway, CPI's Adjustable Cable Runway must be bonded together for grounding purposes. Individual pathway components are bonded across each splice, and the pathway is then bonded to the Telecommunications Grounding Busbar. The grounding thread-forming screws at the end of each cross member and the Grounding Splice Kit ensure proper electrical bonding throughout the system.

What is the load rating?

CPI's Adjustable Cable Runway has a full load rating of 132 lb./ft (196 kg/m) when the runway is supported every 5 ft (1.5 m).

Get a Quote or Talk to Our Team