Choosing the right thermal management solution—whether a filter fan or cooling unit—is essential for keeping your equipment running efficiently and preserving your industrial enclosure’s IP- or NEMA-rated protection.

With numerous options available, this guide will help you choose the right thermal management solution for your industrial enclosure, with practical tips and product recommendations.

Filter Fans vs. Cooling Units: Which Is Right for You?

Filter Fans: Efficient for Low-Dust Environments

Filter fans with matching exhaust fans are best for environments with minimal dust where equipment can handle slightly higher temperatures. They allow ambient air to circulate while filtering out debris.

Key Considerations:

Tip: Pair intake and exhaust fans for effective airflow, and ensure the fan matches the enclosure’s IP or NEMA rating.

Cooling Units: Reliable for High-Dust or Precise Temperature Control

Enclosure-mounted air conditioners are best for environments with heavy dust, moisture, or when tight temperature control is critical. They maintain a sealed enclosure to protect against contaminants.

Key Considerations:

Tip: Choose a unit with extra capacity if you plan to add more equipment in the future.

How Are Cooling Units Different from CRACs?

Unlike Computer Room Air Conditioners (CRACs), industrial cooling units have fixed set points, circulating air continuously to maintain a stable temperature. The compressor cycles off once the target temperature is reached, but fans run constantly at a steady rate. These units are tailored to the specific heat load of the equipment inside the enclosure, ensuring consistent performance.

For mission-critical enclosures, a redundant cooling unit can be added, typically cycled rather than run simultaneously, to maintain reliability.

How to Calculate Airflow Needs for your Enclosure:

1. Gather Key Details: Measure the enclosure size, assess ambient conditions (dust, moisture, temperature), and calculate the total heat load from your equipment (in watts).

2. Understand Cooling Metrics:

3. Use online tools like Pfannenburg’s Sizing Software (PSS): The tool will recommend the appropriate airflow (CFM) for filter fans or cooling capacity (BTU/hr) for air conditioners, tailored to your setup.

Here's how to use this tool:

-

Include ambient conditions. Provide details about the surrounding environment, including ambient temperature and whether the enclosure is in a dusty, wet, or extreme-temperature area.

4. Get Expert Help: For unique requirements, get in touch with a thermal management expert or product specialist from Chatsworth Products for personalized assistance to ensure you select the best solution.

Thermal Management Accessories for Industrial Enclosures

Chatsworth Products offers a wide range of cooling accessories to pair with our RMR® Industrial Enclosures:

Cooling Units

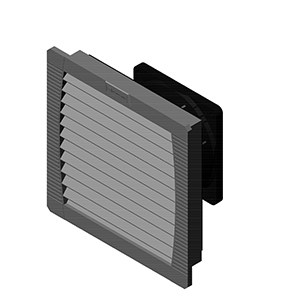

Filter Fans

|

Features a patented quick-mount system for easy installation, offering robust protection and efficient cooling.

|

|

Facilitates airflow while filtering out contaminants, making it ideal for intake applications with minimal pressure loss.

|

|

Designed to work with filter fans, this kit effectively expels heat while enhancing cooling performance and maintaining protection.

|

|

Mounted on the top of enclosures, this fan efficiently expels heat, making it perfect for enclosures with high heat loads.

|

Accessories

|

A durable, easy-to-clean filter designed for dust-free areas, offering a cost-effective and long-lasting solution.

|

|

Extends filter lifespan by up to 300% compared to conventional filters, making it an ideal choice for cost-conscious, high-dust environments.

|

|

Designed for compatibility with CPI fans and cooling units, these cords ensure a reliable power supply and seamless integration.

|

Why Choose RMR® Industrial Enclosures?

Chatsworth Products (CPI) offers the RMR® Industrial Enclosure line, paired with CPI’s thermal management accessories all designed to meet stringent IP and NEMA standards.

Explore CPI’s full range of RMR® Industrial Enclosures to provide the ultimate protection for your equipment.